The world is encountering tremendous economic and ecological changes along with challenges. The futuristic technologies are all set to transform the outlook of Internet of Things (IoT). Today energy supply to millions of communicating devices is a key issue.

On a large scale, renewable energies have become a major source of energy generation. Fields embracing solar cells that generate energy using sunlight or wind turbines dominate the landscape. This renewable energy for energy generation is also embraced on a small scale. This entire concept is called “energy harvesting.”

Small energy converters harvest energy from light, movement, or temperature differences. These harvested energies are enough to power a wireless sensor and transmit data using radio.

Energy harvesting for radio-based products that are already part of mass production includes four different sources:

- Motion – the press on a switch, moving machine parts, the rotary motion of a handle.

- Light– the sunlight coming inside a room.

- Temperature differences – existing between a heat source like a boiler, radiator, or pipes and the environment and variation between day and night.

- Electromagnetic field – a contactless coil in a cage clamp around a cable controls the meter and calculates the line current.

For each source, different energy converters with different power parameters are present. The energy generation type and the corresponding power yield determine the possible sensor applications.

Enhanced Sustainability:

With the introduction of energy harvesting technology, radio sensors are sustainable as they don’t require cabling or battery power. They are environment friendly as well as cut expenditure.

Replacing a single battery typically costs around $300 US dollars in an industrial environment. Though changing the battery does not consume much time, traveling to the site, locating the sensor, testing the device, and documenting the process increases the labor cost. It is believed that batteries have a good service life, but in reality, companies are often engaged in changing them within one or two years to avoid early failures.

Today, resource-saving and environmental protection are the top priority. The rising cost of copper, the presence of harmful components, and battery safety are some serious issues. Wireless energy harvesting sensors are the best solution that considers both the financial aspect and environmental protection.

In Process for The Industry:

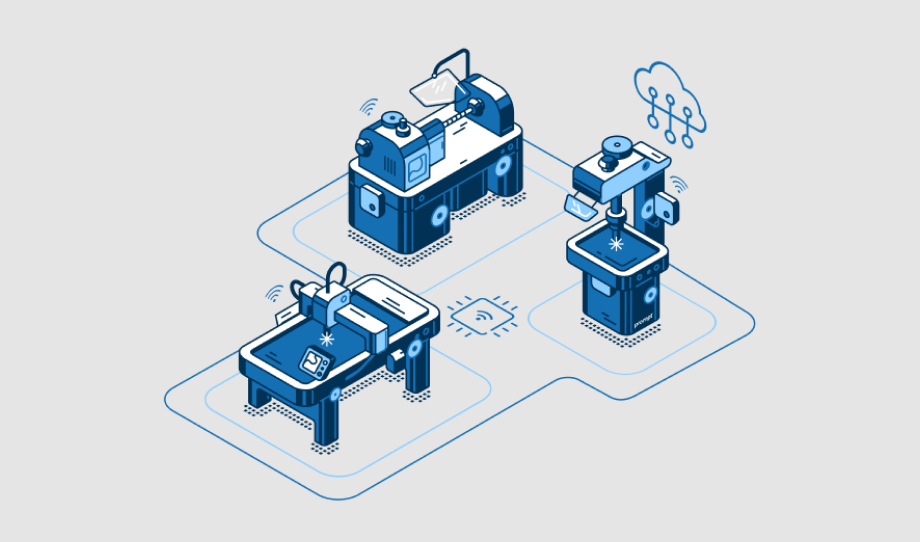

Sensors play a key role in industrial production. They can be used for quality and process monitoring or condition-based maintenance. A wide range of applications is developing in the direction of an industrial Internet of Things (IIoT) with the increasing usage of wireless sensors. Integrating energy-saving radio with local energy converters,battery-free and maintenance-free sensors can be installed directly on moving parts or in hermetically-sealed environments. For instance, it can be implanted to know the position of moving parts, power consumption, temperature of moving parts, liquids, or gases.

Sensors in Quality Control:

Quality monitoring manages the entire production process and ensures the desired properties of the end product based on different parameters.

For this purpose, environmental factors like temperature, humidity, and air quality or process factors like position or temperature are monitored.

Automated monitoring systems require data generated by sensors; for this purpose, sensors must fit seamlessly into existing production processes. Additionally, they must not need special training or generate follow-up costs in the ongoing operation. Therefore the integration of self-powered and maintenance-free sensors provides benefits.

Condition-based Maintenance with Battery-free Sensors:

Besides products, machines also need proper monitoring to ensure a seamless production process. These are prone to high wear, so it would be best to identify problems as soon as possible and take appropriate actions to maintain continuous quality assurance and protection against production downtime.

A primary problem with maintenance planning is the calculation of the intervals between each maintenance cycle. Normally, the interval between two maintenance dates must be as short as possible to detect deviations before any mishappening occurs. Still, each maintenance involves high costs for personnel and idle machines.

It is often possible to derive valuable information by closely examining a few simple parameters. For instance, a temperature rise can indicate higher friction, thus resulting into wear. Wireless temperature sensors can be installed for measurement processes. Humidity sensors monitor water leakage to prevent water damage. Temperature and humidity sensors also inform about air conditions and guarantee good air quality. That is why wireless energy harvesting sensors are best for various industrial applications. They are low maintenance, flexible, and within budget to install.

That is why wireless energy harvesting sensors are ideal for various industrial applications. They are maintenance-free, flexible, and inexpensive to install – outstanding features for assuring high-quality standards and greater sustainability in the Industry 4.0 environment.

IoT in the Factory Building:

IoT allows significantly efficient, adaptable, and individualized production in manufacturing. Using sensors networked with a smart IoT platform, it is now possible to develop a digital twin, i.e., an exact virtual image of a machine throughout its entire life cycle. Digitalization is becoming a part of buildings and will revolutionize them by providing automated service processes in facility management, higher energy savings, and better individual well-being for users. One important thing for factory buildings and industrial processes is battery-free wireless sensors.