Industrial protocols are conversations between industrial automation products for data collection or control. At the beginning of industrial automation, communications were a competitive differentiator, and automation vendors developed communication protocols to leverage technical advantage and lock in their customer base. It has changed with time; today, vendors have extended their protocols and even designated them industry standards to boost adoption. Vendors acknowledged that suppliers with the largest ecosystem of products to choose from, would have a better livelihood of winning parts of a project, if not the complete project. Vendors also learned that it is challenging to be a specialist in all areas of automation. Let’s find out different industrial protocols and those that can be compatible with cloud applications.

Different Types of Industrial Protocols

With time, the manufacturing marketplace has become prevailing by a set of protocols, possibly from the leading suppliers of automation products. Before examining the best-suited for the cloud, let’s know some of the most common industrial protocols. These include protocols such as Modbus, Profinet, CC-Link, Ethernet IP, etc. Many of these are present in different forms to acknowledge varying topologies and purposes eg-dedicated wires vs. Ethernet.

Attempt to bring standardization over the years fetched technology from the OPC Foundation, which was originally Microsoft technology-based, using COM and DCOM Windows technologies for communications between applications. Hence, OPC (OLE for Process Control – OLE that is, Object Linking and Embedding – the technology after COM) is delivered.

1: OPC

OPC obtained standards for accessing data, either subscribing or polling, and the purpose of different data types and how to manage them (Analog and Discrete variables, History Data, Alarms, and Events, among others).

In time, this standardization endeavor shifted from windows technology-centric to operating system-agnostic to aiding Linux and delivering functionality that would be useful to Internet-based communications.

2: OPC UA

The new standard was recognized as OPC UA- with OPC now representing Open Process Communications and UA representing Unified Architecture, one standard to supersede the previous standards that had developed.

3: MQTT

Another technology that is more concentrated on the transfer of messages and less on the content of messages generated out of the need for a very distributed infrastructure with limited bandwidth, as found in the upstream oil and gas market. This protocol is known as MQTT. It is used in the industrial automation marketplace, specifically for cloud communications, and has become very popular in recent years.

4: BACnet

The vertical market shows unique requirements and has supported the requirement for unique developments. BACnet is the leading protocol in the Building Automation Systems (BAS) space. In the Power Generation and Distribution Space, several protocols like IEC-61850, 60870, and DNP-3.

Over time, these protocols have survived on various topologies, and today most of them offer Ethernet compatibility.

Why is the Cloud So Important?

The advantages of cloud computing are numerous and stimulating. They possess:

- Transformation of capital expenditures to operational expenditures

- No need to concentrate on infrastructure management

- Benefiting a constantly scalable architecture

- Furnishing accessibility to your absolute organization, anywhere and anytime

- Benefiting services from domain experts (security, upgrades, solution development)

The cloud can endure different forms, from a solution delivery by industry leaders like Microsoft and Amazon to more scaled offerings for targeted markets. Ultimately, there are hosted solutions, pushing on-premise servers to virtual servers in the cloud, but fully controlled by the IT staff of the organization.

The objective of cloud computing is to provide a lower total cost of ownership by reducing expenses in system management and hardware ownership and the capability to take advantage of solutions offered by others. These third-party solutions are usually built for market purpose and provides multi-tenant capability, letting the service provider handle many customers whilst offering data and user isolation. The concept of cloud computing, specifically for the industrial marketplace, is still in its initial stage, and businesses are fighting with cloud connectivity and the idea of hosting their data to the outside world.

However, the benefits are convincing as it reduces operating costs, and domain experts have developed vertical market applications that require connectivity to the correct data. Additionally, service providers can utilize knowledge gained over their extensive array of customers and offer great value to an individual customer. So, the failure mode of a product in an environment can be predicted by learning about the failure mode in other environments. It helps in potential predictive analytics tuned by the results and anonymization of data from a similar ecosystem of users. While connecting to the cloud, evaluating which industrial protocols best suit the application is necessary.

Things to Consider When Connecting to the Cloud

The best attributes offered by cloud-based solutions fall into two main categories:

- Security ( including access security and cybersecurity)

- Transmission (the quality and reliability of data)

Security is mainly managed using VPNs (Virtual Private Networks). It is an excellent way for bi-directional and ad-hoc communications as it is designed for remote troubleshooting. Using VPNs for ad hoc access, customers can use solutions to secure and broker access to endpoints in a very organized and controlled way. It includes approval processes, windows of access and time limitations, and extra levels of authentication.

For information communication to the cloud, it is becoming more prevalent to utilize public-subscribe models and connection brokers to enhance security. Remote sites will share data to a tight and secure connection. The users of data and cloud applications will subscribe to the data through a broker, eradicating application knowledge of remote communication details that illustrate an exposure. Microsoft IoT Hub is the best example of this technology.

Industrial Protocols for Cloud Connectivity

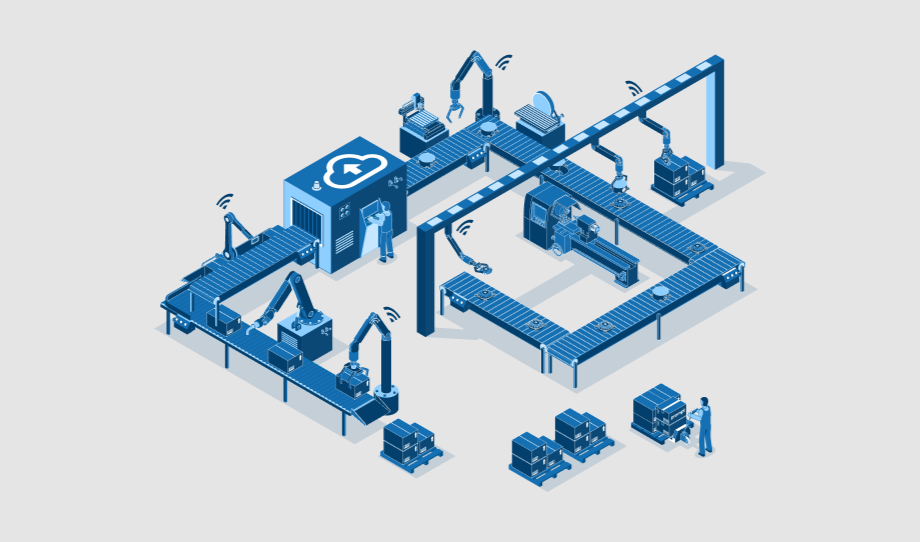

It is optional that all industrial protocols are compatible. Without knowing each protocol and determining if it can be integrated into a cloud, a complete solution to the connectivity issue is to add edge device technology. It will manage the communications to the IT and OT environment and the need for cloud data transfer. Their devices are now covering the market with specific cloud connectivity or a toolkit approach that can be eased their configuration. Most of them are designed with data transfer as their primary function, whereas others support data modeling, visualization, and analytics, in addition to data transfer.

Ethernet is also improving with time in both topology and performance. A more visible improvement is device synchronization and the power to shape traffic. These attributes and other things are Ethernet enhancement called TSN (Time Sensitive Networking). TSN promises the skills to prioritize communications on Ethernet and control traffic bandwidth.

Connecting Safely and Securely

With the expansion of industrial protocols in the market, it is now feasible and easy to connect virtually any automation solution to the cloud with complete privacy, directly or using edge gateways.