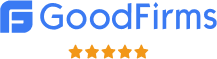

How is IoT Helping The Procurement Team in Improving Productivity?

Today, almost every device is connected; whether it is your smartwatch, air conditioner, or television, we…

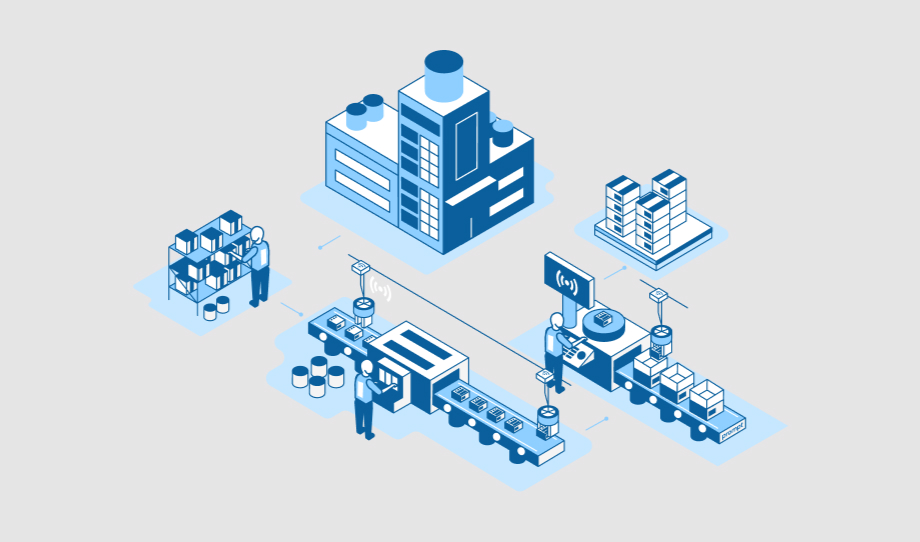

How can IoT Sensors Improve Productivity in Manufacturing?

Internet of Things has been reaching out to almost every sector, and as a result, it…

How Bioengineering and IoT can Increase Agricultural Production?

Today, the Internet of Things is involved in almost everything, which means it is becoming part…