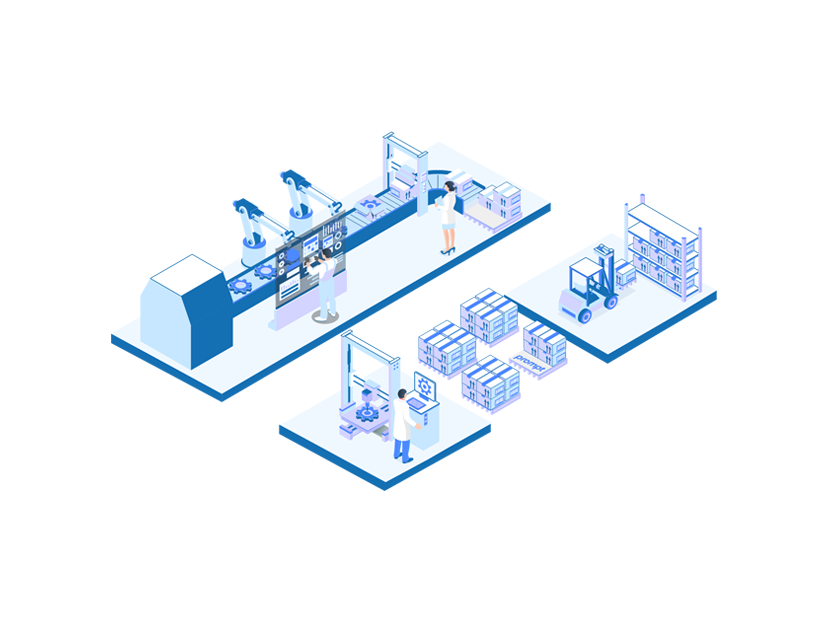

Nowadays, when everything is moving towards automation, then automated factories are no new surprise. Even the smallest operations in factories contribute to success or failure, profit or loss, and productivity.

As business owners are looking for the most efficient, cost-saving technologies, factories have become a new testbed for innovation.

Factory automation leads to the generation of valuable data around processes and allows IoT systems to improve operations smartly and sustainably. This clears that IoT, i.e. Internet of Things holds a great scope in factory automation and provides an unbeatable application to enhance operations, ultimately providing better results. These useful applications showcase a subset of IIoT (Industrial Internet of Things) use cases. Powerful IoT starts with reliable data collection and its storage.

Collecting Data and Unlocking Use Cases:

Thre are several use cases for well-employed IoT technology in a factory setting. Here is the list of few templates:

- Asset Tracking

- Cold chain management

- Patient Safety and health tracking

- Remote monitoring of system health

- Process/Machine lifecycle tracking

In every use case, the process initiates with data collection and storage. IoT usage begins with one end in mind and extends to other applications. After installing sensors in the factory and collecting data, new opportunities and possibilities arise for what and how to use it for producing optimal outcomes.

Other than utilizing basic tracking and monitoring capabilities, using machine learning and other analytics approaches to handle the information communicated by the sensors potentially can boost the business.

Improved Performance and Productivity:

The most important and talked topic for IoT in the factory is how it improves efficiency and productivity. The improved and increased mechanization and automation of physical operations help organizations produce more high-quality speedily.

For instance, IoT allows the remote access and operation of devices that manage materials in an assembly line. IoT systems can employ advanced robotics technology to accelerate assembly line operations, standardize component creation, decrease product waste, reduce product errors and automate QA processes.

Enhancing Inventory Management:

Using remote monitoring of factory equipment and operations can generate data which allows more profound insights into procurement and planning. By managing fill-level tracking of a given material, an IoT system notifies the employees when he has to replenish it. Thus, it can monitor supply over months to analyze how many times the material has to be filled under different factors. It can proactively signal to employees for the supply orders, which ultimately reduces extra expenses and optimize inventory procurement.

Suppose, if there is equipment to be shared within a facility or between the facility, an IoT system can analyze data to recommend where and when the equipment should be transit.

If the particular department experiences a heavy utilization of single equipment on a specific day, say Tuesday, IoT system `will analyze different factors and recommend the quantity and type of equipment to be redistributed on Monday afternoon to optimize inventory usage and assure availability.

Thus, the IoT system can recommend when equipment needs to be preventatively maintained based on collected data on individual equipment usage pattern. Proper integration of IoT with the equipment enables IoT to detect the errors or upcoming maintenance issues. It even informs about the source of errors. This feature saves time and ensures the equipment’s potential use and enhances the equipment operator’s safety.

Enhancing Maintenance of Factory Facilities:

Most of the times, facility maintenance remains one of the underrated areas for factory improvement. An IoT system monitors the ambience and occurring changes. It controls temperature, humidity, and power usage of the factory facility’s HVAC systems, saving cost and energy. It can diagnose irregularities and standard maintenance requirements to help facilities. It can also add security measures into its monitoring to guarantee peace of mind for facility operators.

Increasing Employee Safety:

The reduction in equipment faultiness, product error, and more effective process management are few things offered by IoT systems, ensuring human safety in the factory. Suppose, if any accident happens like fire in a particular section, then the IoT system can transmit critical system information and other supporting data to confirm that employees are informed and safe.

Today, the havoc of COVID-19 has covered the globe. In this critical time, taking proper measures to assure the employee’s good health is the utmost priority. IoT systems can flag COVID concerns by tagging employees to detect when they are close to each other, check their health condition, and map anonymized employee data through more considerable contact tracing efforts. In fact, IoT can also send alerts if there are many people presents in an enclosed place.

Factory automation undoubtedly raises some questions like fewer jobs in the factory, decreased human requirement etc. Factory automation will not snatch the job but free the employees from tedious, repetitive and tiring tasks and shift jobs into process management or system administration. Employees will supervise the systems doing a repetitive job. This will improve employee safety and satisfaction.

Meeting Compliance Measure:

Remote monitoring of factory facilities ensures that compliance KPIs are visible and accessible. By sharing KPIs, automating reports and standard issues early and regularly, IoT integrated system can also help in satisfaction of compliance measures.

IoT just not offers better productivity, inventory optimization, reduced maintenance expense and better employees’ safety but it also supports compliance on different fronts, allowing an organization to create new KPIs that were just a dream earlier.

These unskippable IoT features help reduce financial, material, temporal, legal, and social costs.

Factory automation and involvement of IoT in it can attract immense growth and profits. It provides everything needed for business growth without compromising with the product’s quality or quantity or employees’ health. In fact, it adds much more than you can think of.

Adding IoT in your current your business is not a challenging task; you just need to contact reliable and experienced IoT service providers. The rest process will be like magic. Hence, we can conclude that the depth of possibilities and opportunities with IoT lies in one’s imagination and execution.