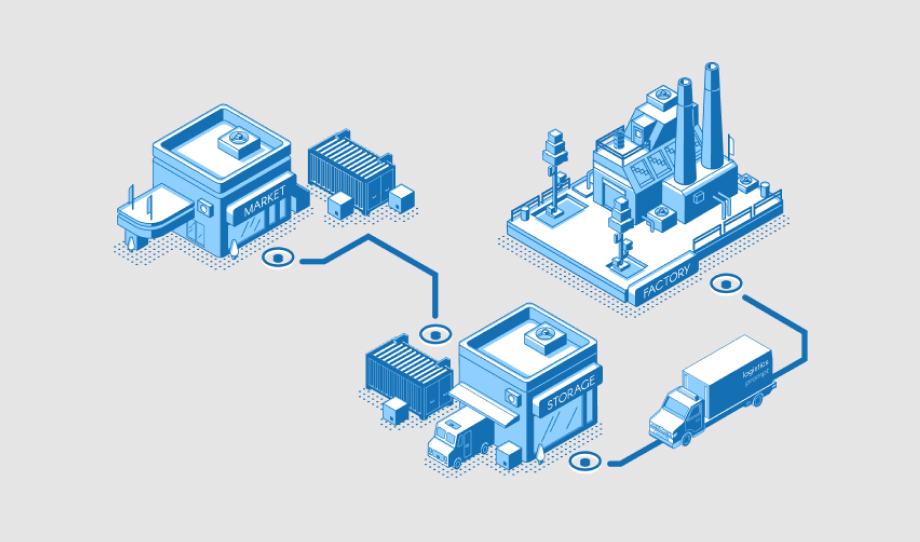

What is the Impact of IoT on Global Logistics Development

We all know that today, the logistics market is dynamic and has become competitive. In the…

How is IoT Helping The Procurement Team in Improving Productivity?

Today, almost every device is connected; whether it is your smartwatch, air conditioner, or television, we…